Bambu Build Plates

The 3rd Anniversary Promotion Time: From Jun. 24th 2025 16:00 (CEST) to Jul. 15th 2025 9:00 (CEST)

- Order will be shipped out from DE warehouse in 1-3 business days once being processed.

- Free Shipping over €55 (most EU countries)

- Free Shipping over €119 (Norway, Cyprus, Malta, Switzerland)

- Shipping rates vary by locations. See our Shipping Policy for details.

Say Goodbye to Print Failures

SuperTack coating provides ultra-strong adhesion to PLA and PETG filaments, even at lower heatbed temperatures. It enhances printing success by eliminating adhesion issues, reduces warping when printing large objects and works well with bad shape surface.

Eliminating Adhesion Issues

Reduces Warping when Printing Large Objects

Long Lasting Performance

The SuperTack coating is durable, retaining its sticky properties even after extensive use. This results in a longer lifespan for the printing plate, reducing printing costs (less than 20% adhesion loss after 300 prints) and lowering carbon emissions.

Smooth & Natural Surface Finish

The SuperTack coating can impart a smooth and matte texture to the bottom surface of the printed object, better blend-in with other surfaces.

Comparison of Heatbed Temperatures for Different Build Plates

| Materials | Heatbed Temperature with Textured PEI | Heatbed temperature with SuperTack |

| PLA | 65℃ | 45℃ |

Excellent First-layer Adhesion and Improved Durability

Self-release when Cooled Down

PEI is an excellent material for 3D printing applications due to its ability to withstand the repeated heating and cooling cycles of a printer heatbed. Prints come off easily when the temperature of the heatbed reaches room temperature, and we always recommend waiting until it reaches 35℃ or lower. If the print is still adheres to the plate, simply bend the steel plate and the model will fall right into your hands.

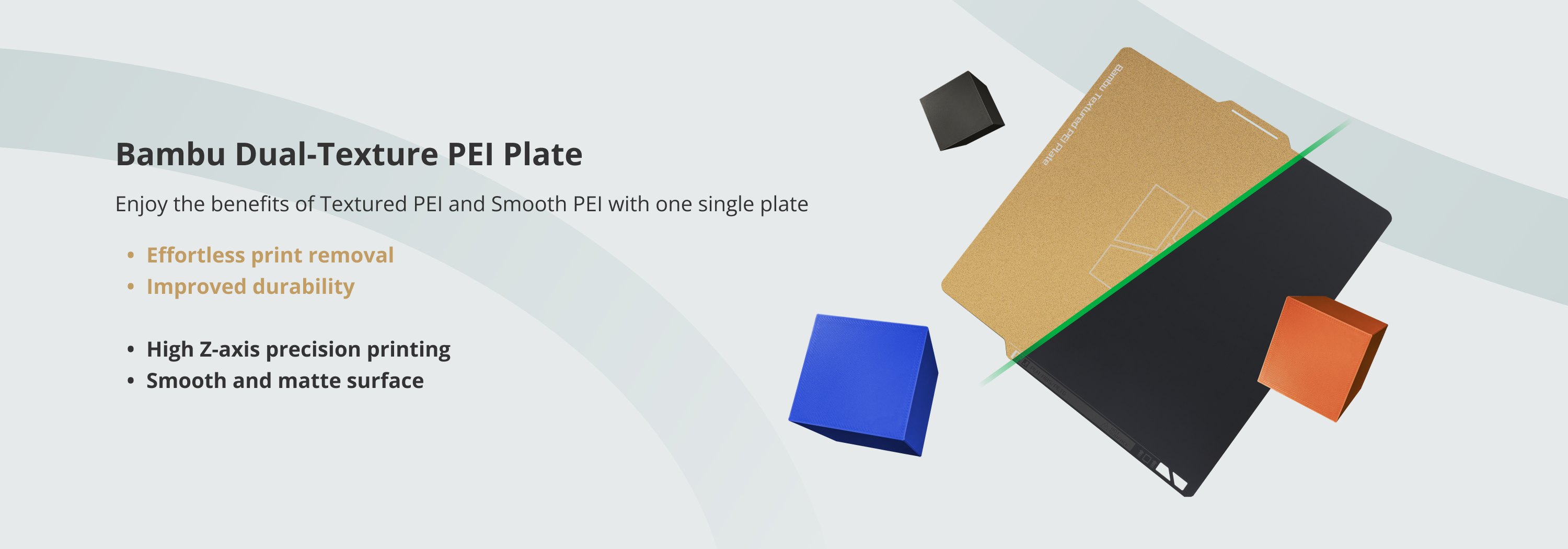

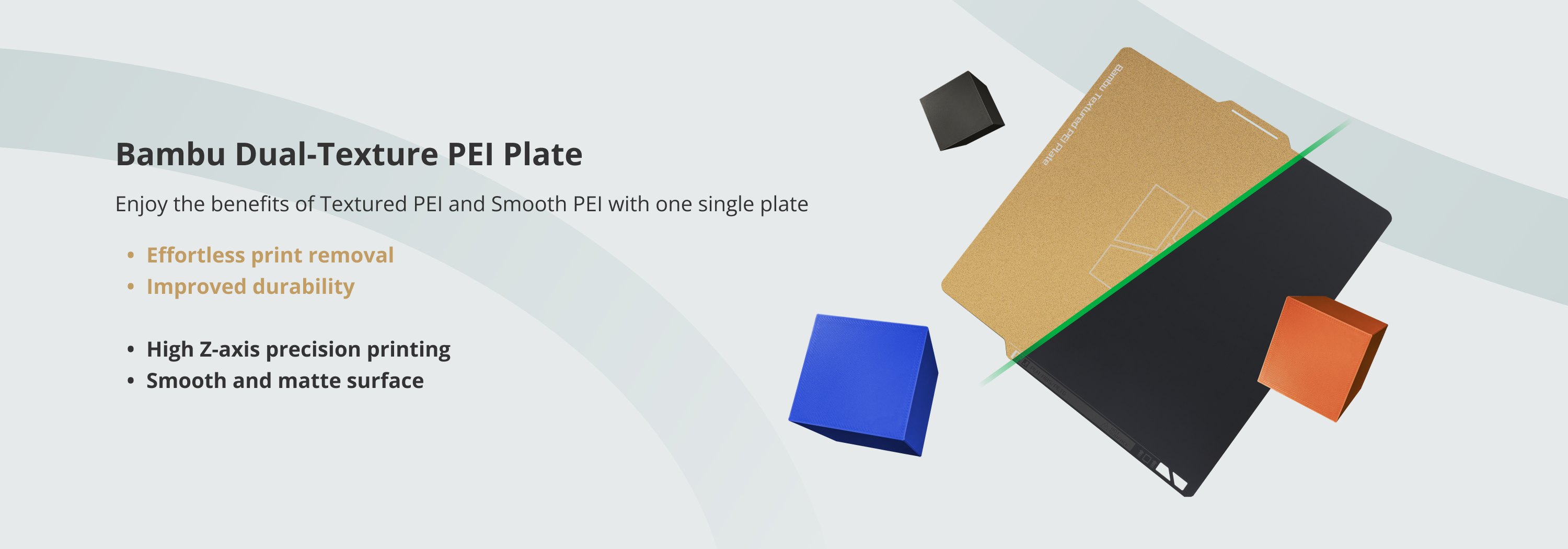

High Z-axis Precision Printing

Smooth and Matte Surface Finish

The use of a specially selected matte PEI sheet can impart a smooth and matte texture to the bottom surface of the printed object, enhancing its overall appearance.

Two Textures (Textured and Smooth) in One Plate

Enjoy the benefits of two different textures in one plate, one side is Textured PEI surface and the other side is Smooth PEI surface. This Plate features a 0.5mm magnetic stainless steel plate that enhances magnetic adhesion and helps to prevent warping and ensure optimal print quality during 3D printing.

Considerations

- For Bambu Cool Plate SuperTack:

- The surface is soft. Be careful when using a scraper to remove printed parts.

- For the Bambu Cool Plate SuperTack, Do NOT print with TPU filament, as it will damage the build plate.

- Increasing heatbed temperature enhances adhesion. Users need to adjust the temperature of the heatbed based on their specific requirements in order to achieve the most suitable level of adhesion.

- Bambu Cool Plate SuperTack is considered a consumable part, which will degrade over time. The warranty will only cover manufacturing defects, not cosmetic damage like scratches, dents, or cracks. Defective sheets upon arrival are the only ones covered by the warranty.

- SuperTack provides good adhesion without adhesive or frequent cleaning. You can clean the surface with water and detergent if heavy dirt appears. Do NOT use organic solvents (especially acetone) to clean the build plate, as it will damage the SuperTack surface.

- Bambu PLA Silk material exhibits strong adhesion on the SuperTack build plate, which may damage printed models. Therefore, we do not recommend using Bambu PLA Silk material on the SuperTack build plate. For users printing with third-party PLA Silk materials, please select the Generic PLA Silk preset in Bambu Studio and evaluate material compatibility based on the specific conditions.

- Deposition of dust and grease on the build plate decrease adhesion. It is recommended to regularly clean the surface with detergent and water to to maintain best adhesion.

- Increasing heatbed temperature enhances adhesion. Users need to adjust the temperature of the heatbed based on their specific requirements in order to achieve the most suitable level of adhesion.

- Carefully sanding the Textured PEI surface with fine-grit (600 was recommended) sandpaper can help restore adhesion.

- If bubbles appear on the bottom of the Smooth PEI sheet, heating it on the heatbed at a temperature of no less than 80 degrees for several hours can be helpful in eliminating the bubbles.

- Do not clean the Bambu Dual-Texture PEI Plate with Acetone, as it will damage the PEI surface.

- Bambu Lab recommends only using Bambu Lab official glue on the Bambu Lab build plates, and can not be held responsible for any damage caused to plates as a result of using third-party glue on build plates.

- Always wait for a few minutes before removing printed models to allow the plate to cool down for easy print removal. This prevents damage to the plate and ensures a long lifetime of the product.

- The Bambu Dual-Texture PEI Plate is considered a consumable part, which will degrade over time. The warranty will only cover manufacturing defects, not cosmetic damage like scratches, dents, or cracks. Defective sheets upon arrival are the only ones covered by the warranty.

Recommended Settings

Please note that other slicer settings might need to be adjusted based on the printed model and the filament requirements

| Materials | Heatbed Temperature | Glue Stick Required for Smooth PEI Surface? | Glue Stick Required for Textured PEI Surface? |

| PLA/PLA-CF/PLA-GF | 45~65℃ | No | No |

| PETG/PETG-CF | 60~80℃ | Glue Stick/Liquid Glue | No |

| ABS (not for A1 mini) | 90~100℃ | Glue Stick/Liquid Glue | No |

| ASA (not for A1 mini) | 90~100℃ | Glue Stick/Liquid Glue | No |

| TPU | 35~45℃ | Glue Stick/Liquid Glue | Glue Stick/Liquid Glue |

| PVA | 45~60℃ | Glue Stick/Liquid Glue | No |

| PC/PC-CF (not for A1 mini) | 90~110℃ | Glue Stick | Glue Stick |

| PA/PA-CF/PAHT-CF (not for A1 mini) | 90~110℃ | Glue Stick | Glue Stick |

| PET-CF (not for A1 mini) | 80~100℃ | Glue Stick/Liquid Glue | No |

Installation Steps for X1 Series/P1 Series/A1

Step 1: Align the plate with the fixed points of the platform with the name of the plate facing you

Step 2: Lower the plate and secure to the magnetic platform

Installation Steps for A1 mini

Step 1: Align the plate with the fixed points of the platform with the name of the plate facing you

Step 2: Lower the plate and secure to the magnetic platform